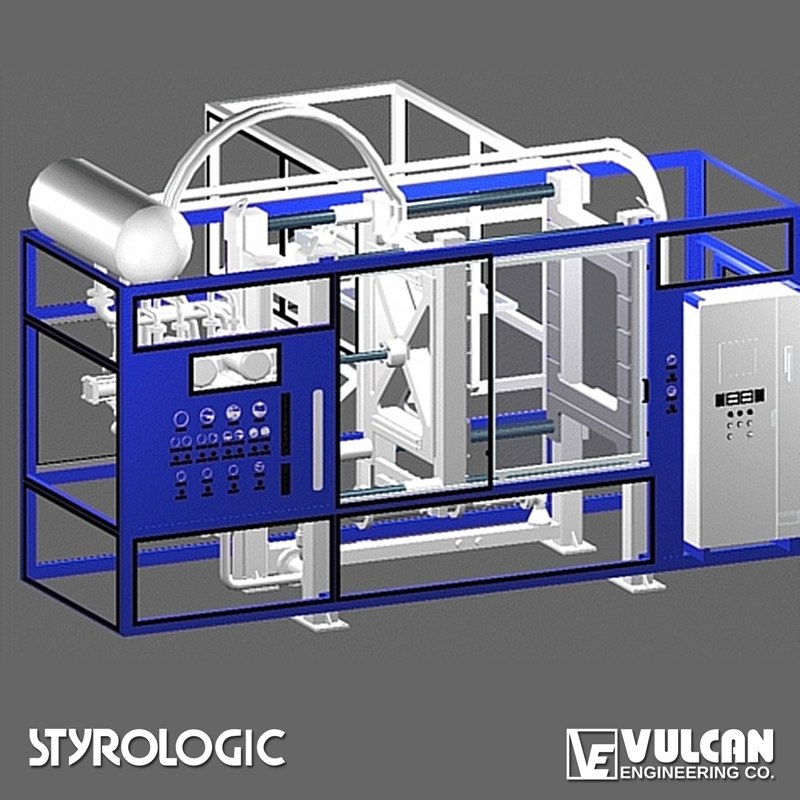

Foam Molding Machine MPH 120/120 is used for producing foam replicas from pre-expanded polystyrene beads. This equipment is specifically designed for the lost foam process.

Foam Molding Machine MPH120/120

Foam Molding Machine MPH 120/120 is used for producing foam replicas from pre-expanded polystyrene beads. This equipment is specifically designed for the lost foam process.

Categories: Foam Molding, Lost Foam

Tags: Foam Molding, Lost Foam, Styrologic

| Electric | 26 HP (20kW) |

|---|---|

| Tool Mounting Flanges (inside) | 47 in x 47 in (1200mm x 1200mm) |

| Max Opening between Mounting Plates | 41 in (1050mm) |

| Max Fill Injector Connections | 25 |

- Horizontal operation (vertical parting line)

- Standard Styrologic steam chest system; chest design allows for positive and quick tooling change

- Tool flange faces are stainless steel

- Adjustable, 2-speed, pressure compensated hydraulic system.

- Four over-sized guide bars, containing expansion compensation bearings, provide quick motion, even load, plate to plate squareness with powerful locking forces

- Pressure bead fill system with a fine tune regulator for producing thin wall patterns; and connections for attaching fill guns.

- Even heat transfers to both tool faces controlled by independent steam valves

- PLC controls for machine functions. All process steps are freely programmed and continuously indicated on panel mounted touch screen operator interface

- Fixed and moving chests have adjustable water dosing system providing efficient atomization of a small quantity of water

- High power vacuum system containing liquid ring pump and accumulator designed for rapid evacuation of steam chests and stabilization of foam pressure along with minimizing foam moisture content.

Vulcan Engineering Co.

Copyright © 2025 All Rights Reserved

Copyright © 2025 All Rights Reserved