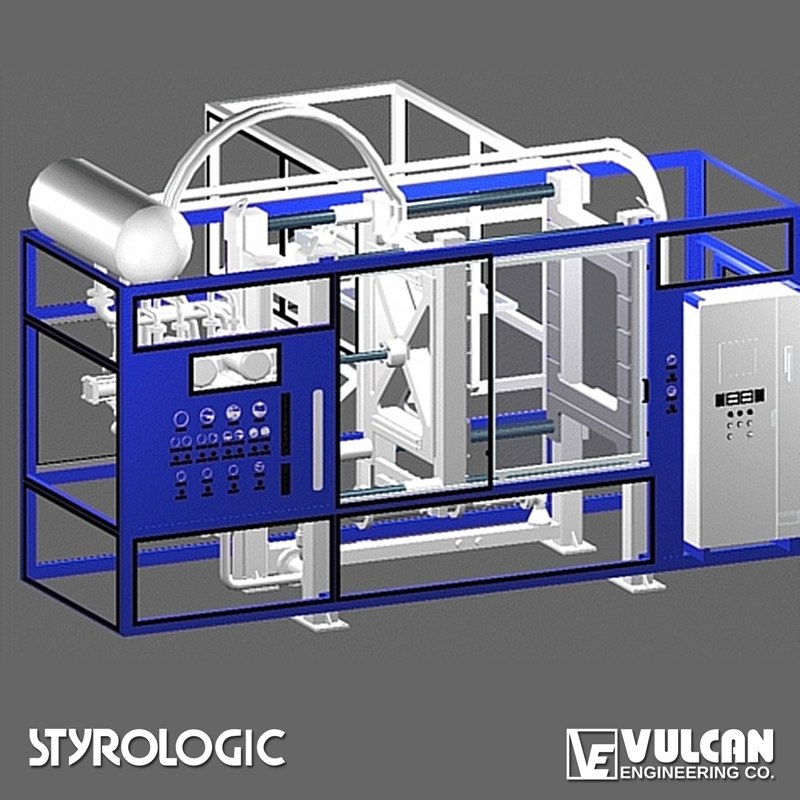

Foam Molding Machine MPH 80/35-A is used for producing foam replicas from pre-expanded polystyrene beads.

Foam Molding Machine MPH 80/35-A

Foam Molding Machine MPH 80/35-A is used for producing foam replicas from pre-expanded polystyrene beads.

Categories: Foam Molding, Lost Foam

Tags: Foam Molding, Lost Foam, Styrologic

| Electric | 17 HP (13kW) |

|---|---|

| Vacuum | 150 M3/hour |

| Tool Mounting Flanges (outside) | 36 in x 18 in (916mm x 464mm) |

| Tool Mounting Flanges (inside) | 33 in x 14 in (840mm x 350mm) |

| Max Opening between Mounting Plates | 46 in (1180mm) |

| Max Fill Injector Connections | 15 |

-

• Horizontal operation (vertical parting line)

- One blow back air pressure regulator

- Even heat transfer to both tool faces controlled by independent steam valves

- Fixed and moving chest has adjustable water dosing system providing efficient atomization of a small quantity of water

- High power vacuum system containing liquid ring pump and accumulator designed for rapid evacuation of steam chests and stabilization of foam pressure along with minimizing foam moisture content

- Direct piped process valving providing high precision and repeatability

- PLC controls for machine functions; all process steps are freely programmed and continuously indicated on panel mounted touch screen operator interface

- Integrated automatic demolding part system provides safe, damage free handling of foam replicas

- Plain language touchscreen operator/machine interface

• Tool mounting is designed to allow for positive and quick tooling change

• Tool flange faces are stainless steel

• Variable speed and pressure compensated hydraulic system

• Four (4) oversized guide bars containing expansion compensation bearings provide quick motion, even load and plate to plate squareness with powerful locking forces

• Moving platen tool alignment set screws

• Bead fill system with transparent vessel and connections for attaching fill injectors

• Pressure fill system with fine tune regulator for producing thin wall patterns

Vulcan Engineering Co.

Copyright © 2025 All Rights Reserved

Copyright © 2025 All Rights Reserved