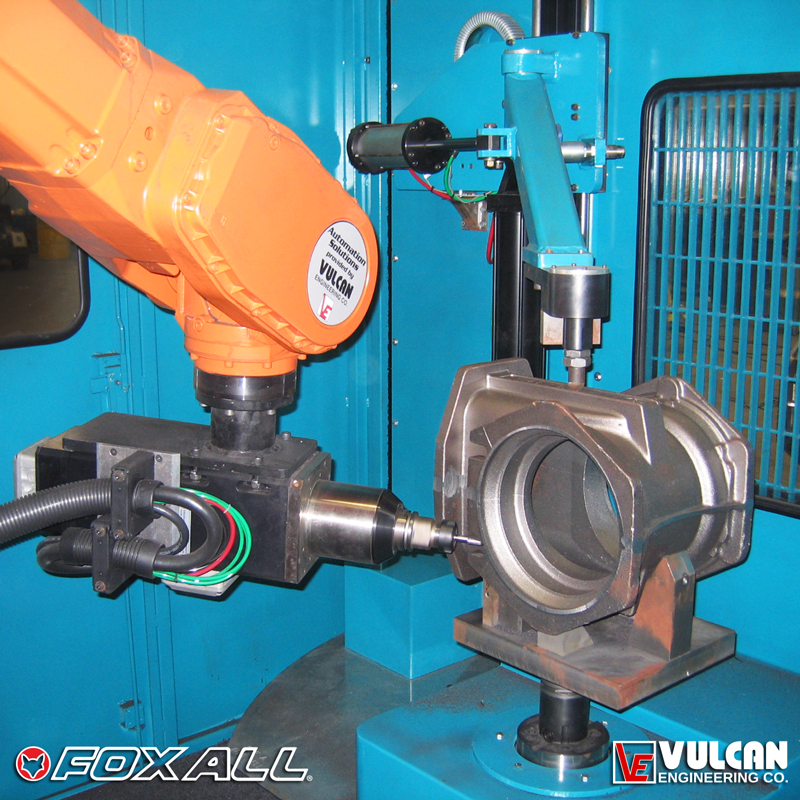

The success of the Foxall® design is due to the adaptable robust design using only proven technology. The core component of the Foxall® is a Foundry Protection package Robot. The robot gives maximum accessibility to the casting, with precise control giving a consistent quality finished product. Process consistency provides significant reduction in scrap rates.

The robot is equipped with the latest in spindle technology with HSK tool change giving total control over cutting tool speeds and feeds and enabling the user to accurately monitor cutting tool life and performance. The Foxall® is not, as with other finishing machinery, limited to one or two tools. The unit can be equipped with a tool rack and active tool change. These tools are then selected within the robot program giving the Foxall® the ability to multi-process. The rack can be fitted out with super abrasive wheels and burrs, standard abrasives and cut-off blades in any combination.

**Features and options subject to change without notice**