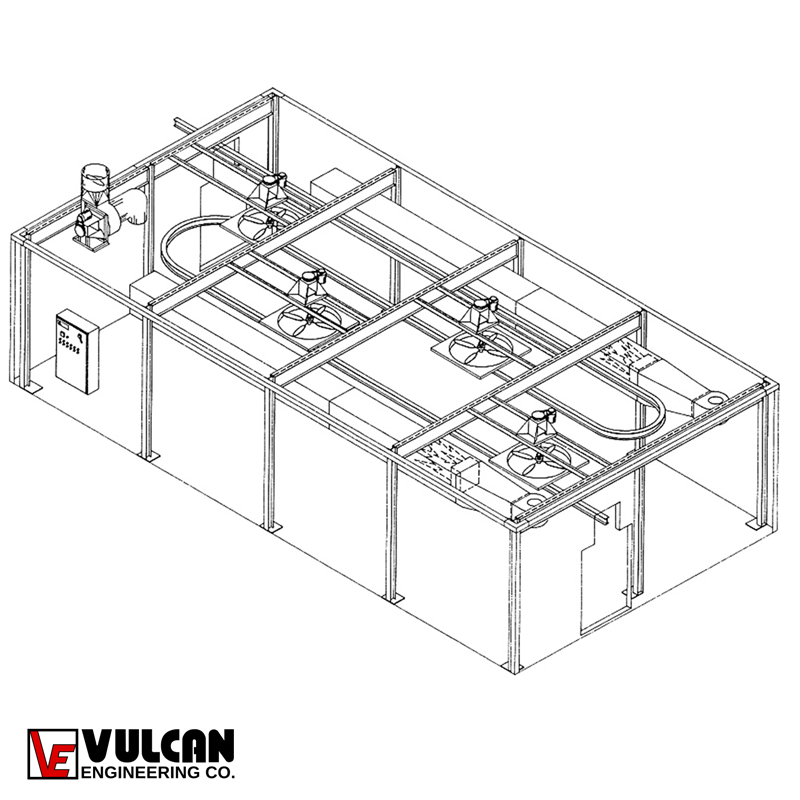

The convection oven can be used for different applications such as drying, preheating or curing. The Convection Oven distributes hot air by direct or indirect fired design throughout the oven enclosure through a series of duct-work.

High temperature supply and exhaust fan circulate the heated air for maximum uniformity. Made from structural steel frame and aluminized panel skin over-stuffed with fiberglass insulation, the oven is constructed for minimal heat loss and maximum energy utilization.