Developed from Vulcan’s Robotic Grinding compliant technology, the system provides high metal removal rates by applying the correct grinding force throughout the process. Much faster than traditional rise and fall table grinding technology. The system uses a replica of the part to be processed, the replica mounted on the same axis and/or plane as the part is driven into a steel wheel that is the same diameter as the contact wheel. The compliance system on the grinder provides a constant grinding force for optimal metal removal. The part is rotated or moved vertically on the Accufast table until the replica contacts the steel guide wheel which then finishes the part to match the replicas profile. Watch the video of the machine in operation for a full understanding of its capabilities.

Product categories

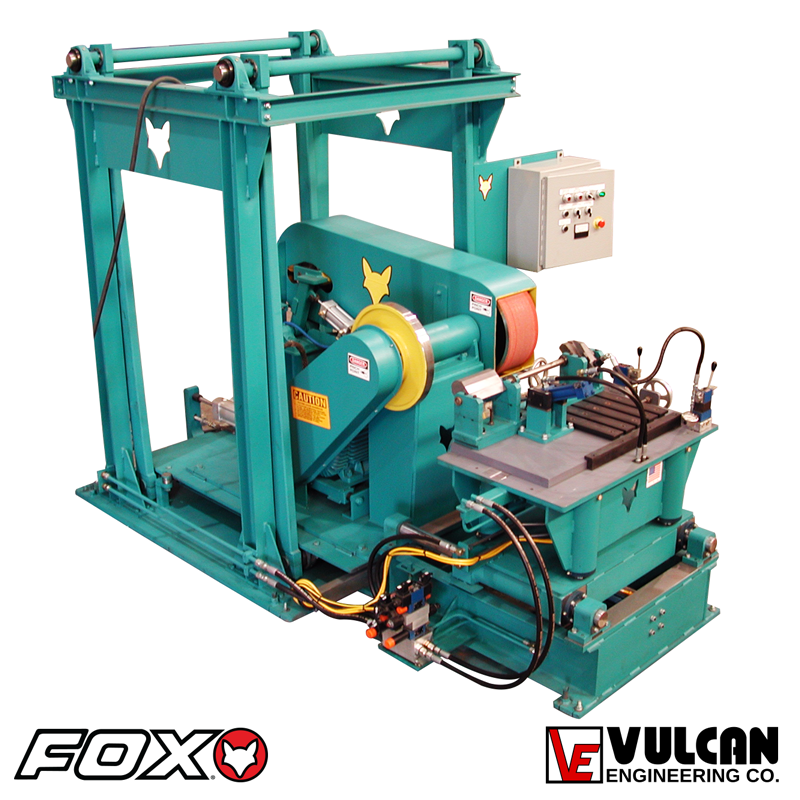

Fox® Semi-Automatic Compliant Belt Grinder

Developed from Vulcan’s Robotic Grinding compliant technology, the system provides high metal removal rates by applying the correct grinding force throughout the process. Much faster than traditional rise and fall table grinding technology.

| Belt Speed | 7,500 SFPM (2,885 SMPM) |

|---|---|

| Belt Size | 8 in wide x 132 in long (200 mm wide x 3350 mm long) |

| Belt Change | Air-tensioned idler allows quick belt changes. |

| Belt Sensors | Sensors are provided to detect belt breakage and to initiate machine shutdown and grinding table retraction to prevent equipment damage and prompt belt replacement by the operator |

| Spindle | • Heavy-duty sealed spindle, a proven FOX design. |

| Motor | 50 HP |

| Contact Wheel | • 18 in Diameter x 8 in Wide (460 mm Diameter x 200 mm Wide) • Steel Wheel. |

| Structure | Compliant mounting structure for Grinder |

| Accufast pressure feed System | • The rise and fall grinding table supported by Nylatron bushings on four (4) induction hardened, chrome plated guide bars • 6 in (150 mm) of grinding table travel • Table designed to accept different grinding fixtures |

| Fixture Table | • Grinding fixture table will be mounted on a FOX Rise and Fall Grinding Table • Grinding fixture table with T-slots to facilitate mounting a part rotating device and/or other fixtures. • Grinding fixture table will be supported by Nylatron bushings on induction hardened, chrome plated guide bars. |

| Hydraulics | Hydraulic unit to operate rise and fall table and any hydraulic clamping fixtures |

- High Metal removal rates at optimal Grinding pressures

- Less part heat over conventional methods

- Quick changing of fixtures

- Easy step up with minimal or no adjustment necessary

- Precision regulator to adjust grinding force

- Complete usage of grinding belt media as the system does not require oscillation

- Designed for the foundry environment

Cam Rotator

- Hydraulic rotary actuator for part and cam rotation

- Cam hub for mounting of part cams

- Part fixture hub, shaft and bearing blocks for mounting of clamping fixtures

- Base plate for mounting to fixture table utilizing T-slots

Fixtures for Cam Rotator or Vertical Grinding

If you are unable to watch this video because of software or network restrictions, please contact us. We would be glad to send you a copy of the video. For more information Click Here >>

Call Us: +1 (205) 663-0732

News

Copyright © 2024 All Rights Reserved