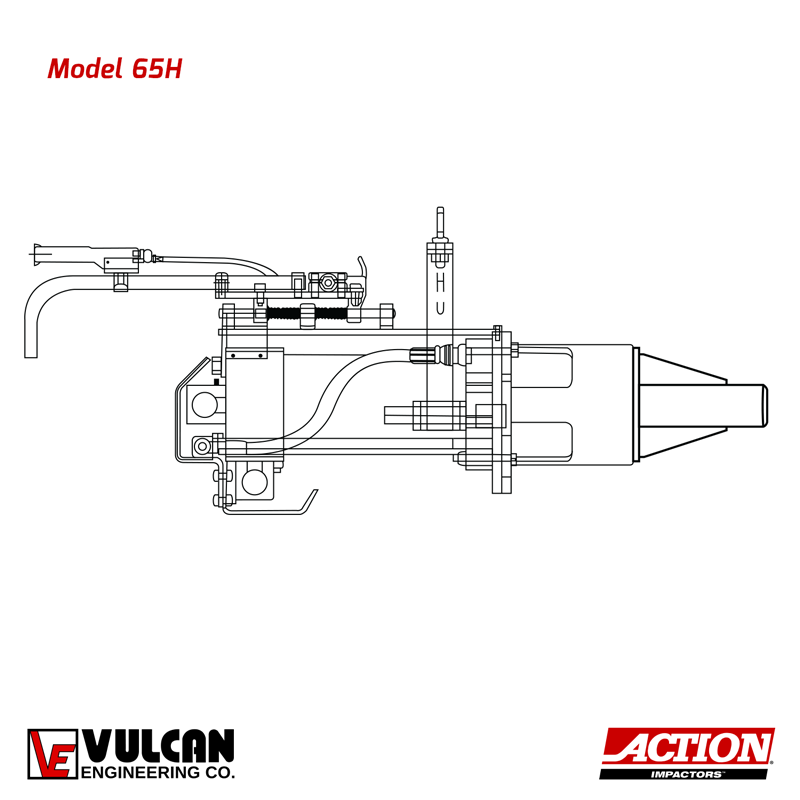

The Action® Impactors™ is designed to remove risers quickly and efficiently. Shock absorbing handles and cushion assembly provide long life and less wear and tear on the operator. Major feature is the ability to dry fire the Impactor™ without damage to the machine, a major advantage over competitive models. One machine can replace several people using sledge hammers.

The Impactor™ is operator-friendly (ergonomic grips, shock cushioning), and are built to withstand the rigors of continuous foundry use. Manually operated Impactors™ are typically suspended by a chain-fall hoist, supported by a jib crane or similar device.

Most Productive

The Impactor™ is capable of rapid firing, which saves time and keeps the operator working.

Most Reliable

Uses a one-piece rod and piston, eliminating the inherent weakness of an assembled multi-component rod and piston assembly used by some competitors. This means greater reliability and energy transfer.

Dry-fire safe

Action® Impactors™ have been tested under sustained and rapid dry-fire situations. The Action® Impactor™ did not fail after 800,000 dry-fires. The competition recommends not dry-firing their units. It is important to note that the unit is essentially dry-fired whether a riser is broken or missed, because the momentum of the rod propels it into the cushion piston and the energy must be absorbed.

Designed for maximum up time

Highest quality components and innovative designs are assembled and arranged for easy service.

Continuous Research and Development

Continuing R&D provides the Customer with a superior product. Our years of experience in Impactor™ design have resulted in the development of many service life-enhancing features, including specially formulated cushion piston material, superior performing seals, improved rod hardening processes, protective guards, shock-absorbed handle bar assemblies, and several other time-tested features.

Special Cushion Chamber

Protects Impactor™ when operator misses target. This feature is an exclusive design—a vital feature that prolongs the product’s life.

Action® Air Quality System

- Heavy-duty air filter extends life of seals and other components.

- Heavy-duty air-water separator removes water to prevent corrosion and optimize performance.

- Heavy-duty precision lubricator injects the exact amount of lubricant required for optimum operation of Impactor™.

- Mounted on a compact fabricated steel stand

- Interconnect hose, 30 feet (9m) length

Handgrip-mounted Hoist Controls

Electric or pneumatic push button station mounted to the Impactor™ to control customer provided hoist for faster reorientation of the unit.

Integrated Intensifier / Air Quality System

- Complete pneumatic unit provides higher usable outlet pressure up to 150 psig (10 bar).

- Integrated tank, gauge and valve

- Integrated Action® Air Quality System

- Mounted on a compact fabricated steel stand

- Interconnect hose, 30 feet (9m) length